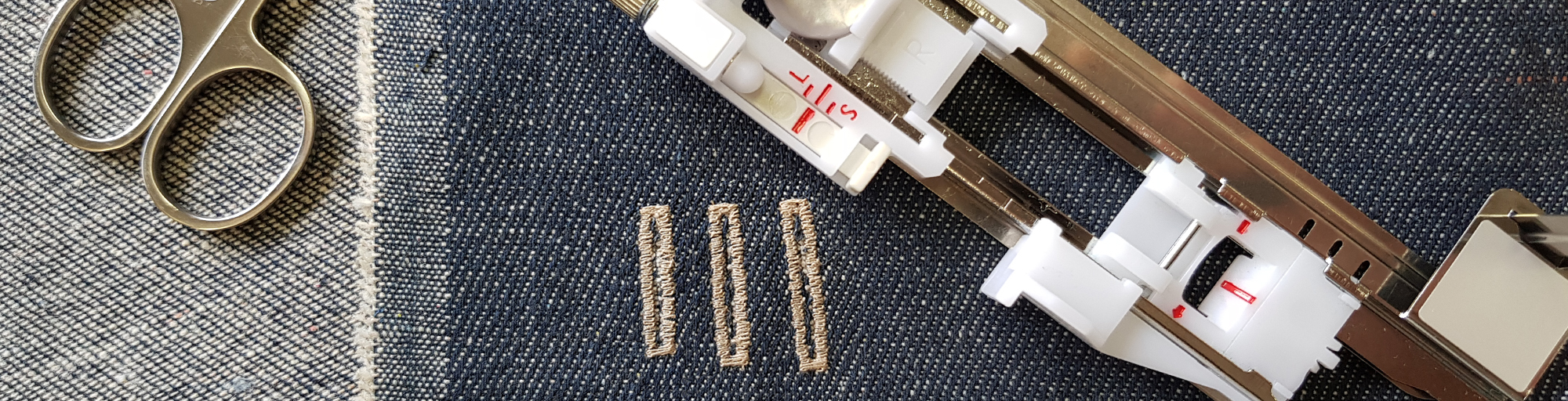

Buttonholes With A Snug Fit

When it comes to buttonholes, the perfect fit is key. Long gone are the days when you need to manually mark out the size of each buttonhole, making it a guessing game as to whether you’ll actually have a reliable closure on your garments.

Many of Janome’s modern sewing machines today come equipped with a one-step buttonhole foot and a stabilizer plate for effortless buttonhole creation. You can sew buttonholes of the appropriate size by simply placing your button into the button holder of the foot and pushing the clamp right up against the button. The foot will measure the size of your button and ensure the buttonhole is made to the correct size.

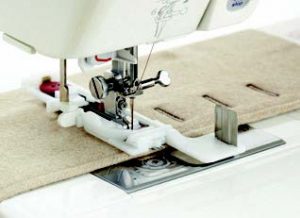

Button placed into the foot – this does the sizing of the buttonhole automatically for you.

When the buttonhole foot is attached to the buttonhole stabilizer plate, the machine will feed various kinds of fabric and uneven layers more smoothly instead of eating the fabric or causing the needle to get stuck in position.

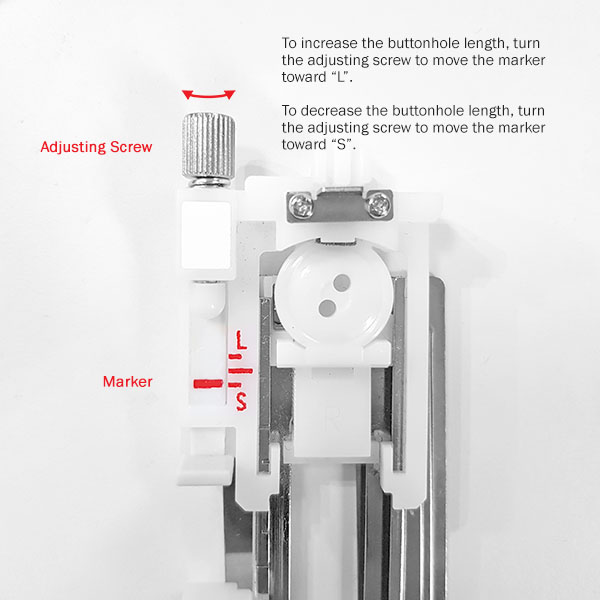

If you have an older model, you might have a one-step buttonhole foot which looks similar to the one pictured below, except that it may not have the more advanced feature of lengthening or shortening the buttonhole.

This upgraded one-step buttonhole foot comes standard with all 9mm Janome sewing machine models. Basically, it allows you to tweak the length of your buttonhole slightly to accommodate knit/stretch fabrics or domed buttons.

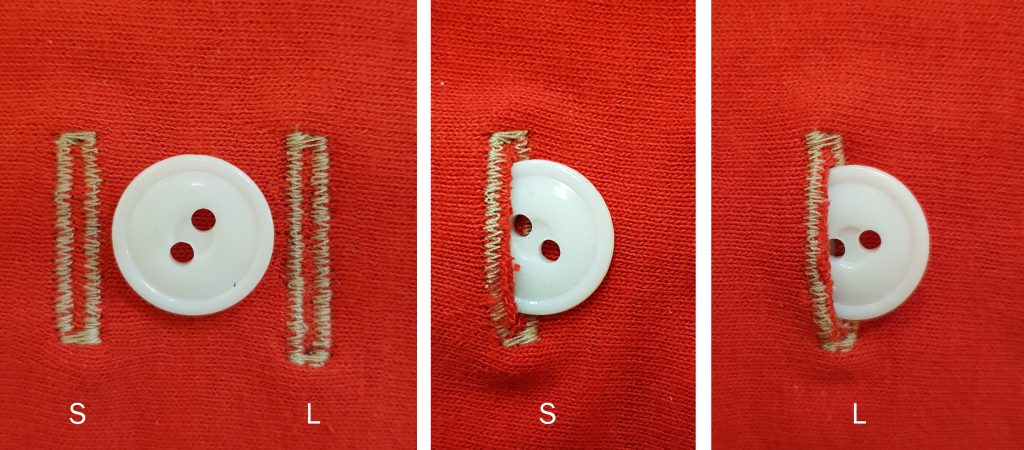

By adjusting the screw to the left or right, the marker will move to L – for long, or S – for short, thereby increasing or decreasing the buttonhole length.

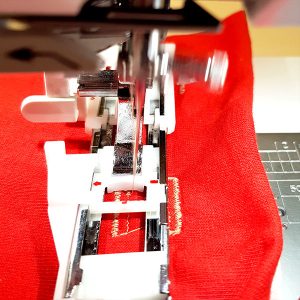

When working with knit fabrics, such as a stretchy T-shirt which may be more prone to tugs and pulls or get stretched during a machine wash cycle, a slightly shorter buttonhole will ensure the button remains securely in place once buttoned.

A shorter buttonhole on knit fabric can prevent the button from slipping out.

On the other hand, if you’re dealing with heavy fabric or using domed, thicker, or handmade buttons, you may require a larger button hole.

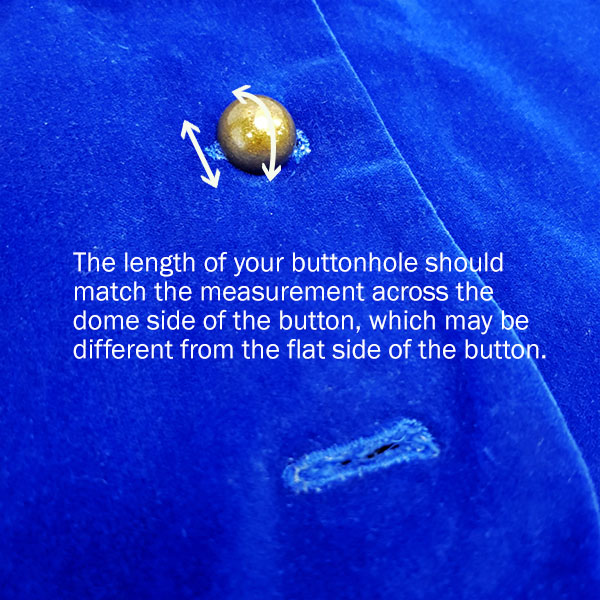

Have you ever measured your button, sewn your buttonhole, only to find that it still isn’t big enough?

This is often the case when the thickness of the button hasn’t been taken into consideration. For example, a dome shaped button might be 1/2″ wide from end to end, but if you measure across the dome you will notice that it is slightly longer.

To take the thickness of the button into account just add a little length to your buttonhole to accommodate the button. You can adjust your one-step buttonhole foot slightly by adjusting the marker to the L position.

The upgraded one-step buttonhole foot and stabilizer plate are great tools to have for making all the difference when sewing buttonholes.

If your machine does not come with them or is not of a compatible model, you are most welcome to discuss your options with an authorised Janome stockist, who might suggest upgrading to a machine which offers these fantastic features.

Oops! We could not locate your form.