Sewing Basics – Know Your Needles

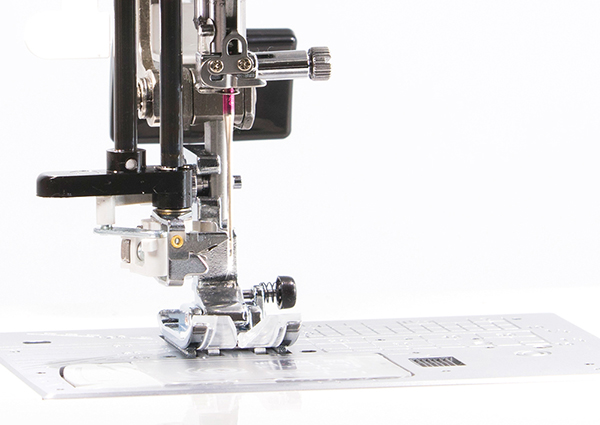

No matter how advanced or sophisticated sewing machines have become, the basic operation of a sewing machine stays pretty much the same: the needle does the work – pulling top thread to meet the bobbin thread to form a stitch.

Because it’s so small and largely unnoticeable, sometimes it’s easy to overlook the importance of your sewing needle. What many people don’t realise however, is that the needle has a tremendous impact on your project. Not only does it affect how you stitch, it also affects the overall look and quality of your work.

Think of it this way: a good needle in your sewing room is like a good knife in your kitchen!

You probably already know this: the average sewing life of a needle is 8 hours. When a needle is piercing your fabric at 600 to 1,600 stitches per minute, that is TEN times per second at 600 SPM. Small things like a blunt point or an eye that’s beginning to wear, can make a big difference in the quality of your stitches. A good rule of thumb is to use a new needle at the start of every project, ensuring less issues and great sewing results.

Additionally, using the correct Janome needle for the fabric you are sewing will help you achieve optimum stitch results from your sewing machine. Today we’ll take a closer look at the different sizes and types of Janome needles available.

For starters, let’s get to know your way around a needle.

1. Needle Anatomy

All sewing needles have essentially the same parts:

Shank: The upper end of the needle, which is inserted into the machine. On the vast majority of domestic needles, the back of the shank is flat to make it easier to correctly insert them. (Round = Front | Flat = Back)

Shaft: The body of the needle below the shank. The size of the needle is determined by the diameter of the shaft. The smaller the number, the smaller the shaft will be. The eye will increase in size proportionately to the size of the shaft.

Front Groove: This groove, located on the front of the shaft, is designed to allow the thread to lie tightly against the needle as it passes through the fabric

Scarf: The short indentation above the eye at the rear of the needle. It allows the hook to catch the thread loop, made by the needle, to form the stitch. Janome speciality needles are designed to have a longer, deeper scarf to help eliminate skipped stitches.

Eye: You know what this is – the hole at the bottom of the needle through which the thread passes. Janome needles have especially smooth eye holes to keep thread feeding smooth and to avoid snagging.

And finally the Point penetrates the fabric, allowing the needle to deliver the thread to the hook to form the stitch. There are different Points designed to penetrate different types of fabric.

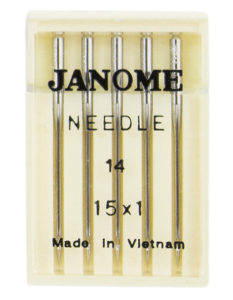

2. Needle Sizes

Sewing machine needles come in an assortment of sizes designed for optimal sewing on different weights of fabric. Quite simply, the finer the fabric the finer the needle; the heavier the fabric the heavier the needle.

For example, if you are going to sew a sheer window curtain, you would want a fine needle such as size 9 or 11 to penetrate the light weight fabric. Using size 16 needle would leave giant holes in your fabric. With heavier home décor fabric such as wool and velvet, a larger size needle would offer extra strength and be less likely to cause stitching issues.

Tip: Keep an assortment of needles on hand to make it easy to choose the appropriate needle for each project.

3. Needle Types

Traditionally when fabrics were only made of natural fibres, changing to specialty needles wasn’t that critical. With the large variety of synthetic fabric on the market today, knowing your fibre content, weave and weight of the fabric are all considerations when choosing the right needle for your machine.

Janome Universal Needles also known as Regular Sharp Needles are used for general sewing of most woven fabrics. This includes chiffon, linen and wool.

Janome Ballpoint Needles have a rounded point and can slip between the yarns to prevent damage to knitted or stretch fabrics such as jersey and fleecy fabric. Janome Ballpoint needles also have a special scarf to eliminate skipped stitches on these types of stretchy fabrics.

Blue Tip Needles are one of our most popular needles for machine embroidery and light to medium weight stretch fabrics. Blue Tip needles have a ballpoint tip, so that when stitching with light fabrics like organza, there is less tendency for both the fabric fibres and embroidery stitches to break down.

Red Tip Needles are size 14 needles with a ballpoint, with added strength and durability. Made for stitching dense embroidery designs and when using metallic embroidery threads. The larger eye allows metallic threads to flow through without catching and breaking.

Top Stitch Needles are size 14 needles with a sharp point, with added strength and durability. The larger eye on this needle accomodates for the heavier weight top stitching threads.

Other specialised needle types:

Denim: Has a very sharp acute point and a stronger shaft for denim, canvas and other tightly woven fabrics. Its eye also accommodates denim thread, being thicker than standard sewing thread.

Leather: Features a 3-sided chisel point which cuts clean through leather. It can also be used on vinyl, suede and rubber backed fabrics.

Purple Tip: Purple Tip needles have a special shaped cobra head with a ballpoint tip. This head design allows the stitch to be properly formed, when stitching knit and tricot fabric, ordinary sewing, free motion quilting and when embroidering. The Purple Tip needle is also designed to help prevent skipped stitches when stitching on these types of fabrics, or when embroidering.

Janome also offers a range of high quality specialty Organ needles that perfectly complement our sewing machines. Click here to find out more.

When it comes to accessories for sewing and stitching, few tools are as important and functional as the sewing needle. Make sure to ask your Janome dealer about genuine Janome Sewing Needles the next time you pop into a Janome store.

Oops! We could not locate your form.